The quality of the films to be used is determined by the surface structure of the substrates to be protected, as well as by the stresses placed on the films by the downstream processes. We will be happy to provide you with our know-how for the correct selection of the protective film in your process.

Protective films

The quality of the films to be used is determined by the surface structure of the substrates to be protected, as well as by the stresses placed on the films by the downstream processes. We will be happy to provide you with our know-how for the correct selection of the protective film in your process.

Protective film for metal surfaces during laser cutting for fibre and CO2 lasers

Intended use

Nitto FIBERGUARD™ 509H10P and Nitto FIBERGUARD™ 511M10P

Nitto FIBERGUARD™ black film reliably protects metal surfaces during fibre and CO2 laser cutting. It is specially designed for high speed and high power laser cutting machines.

Advantages

The film can be used for both laser systems.

FFT supplies you with the surface protection film quickly and reliably, in various sizes and already in small quantities.

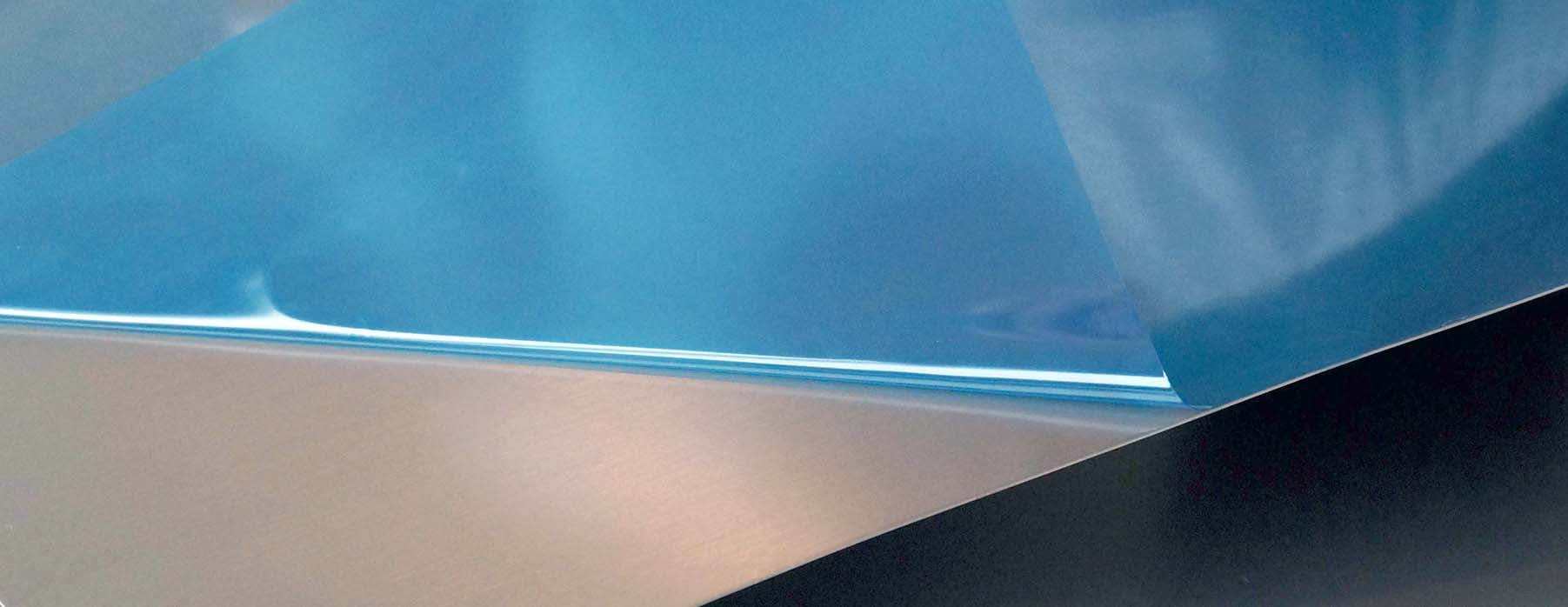

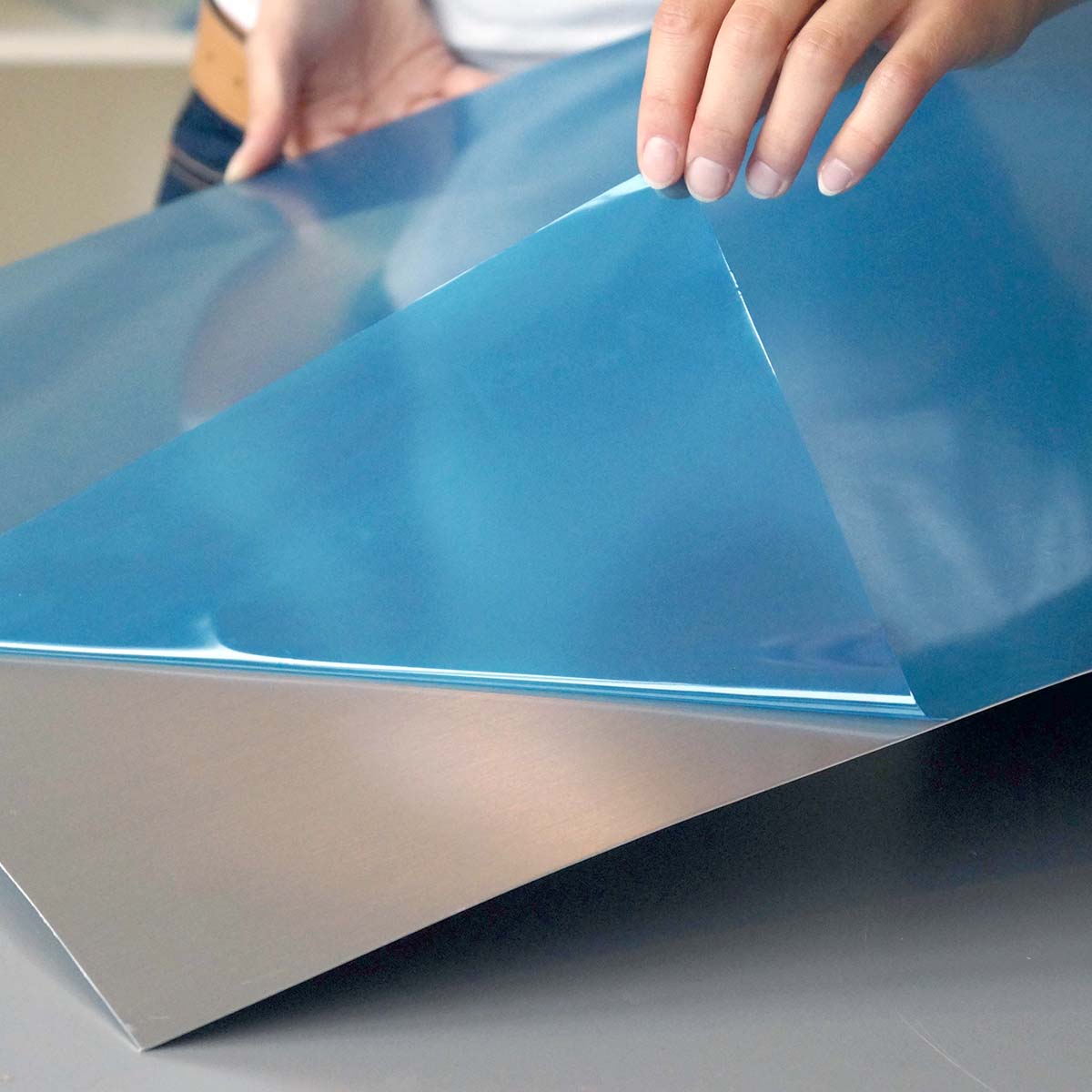

Protective films for metals

Intended use

Protective films for the temporary protection of metals with all common surface qualities.

Whether rough/textured or high-gloss, aluminum, stainless steel, copper or brass, FFT will find the optimal protective film to safely protect your high-quality surfaces by selecting the right carrier and adhesive.

Advantages

Coils, sheets or profiles – easy removability without leaving adhesive residues is a prerequisite. By selecting an “Easy-Peel” film, maximum productivity in further processing can be enabled.

Protective films for plastics

Intended use

Protective films for the temporary protection of plastics with all common surface qualities.

Whether laminates with different degrees of gloss, extruded profiles or displays, FFT finds the optimal solution to safely protect your high-quality surfaces by selecting the right carrier and adhesive.

Advantages

ABS, PC, PMMA or PVC – their easy removability, without leaving adhesive residues, is a prerequisite.

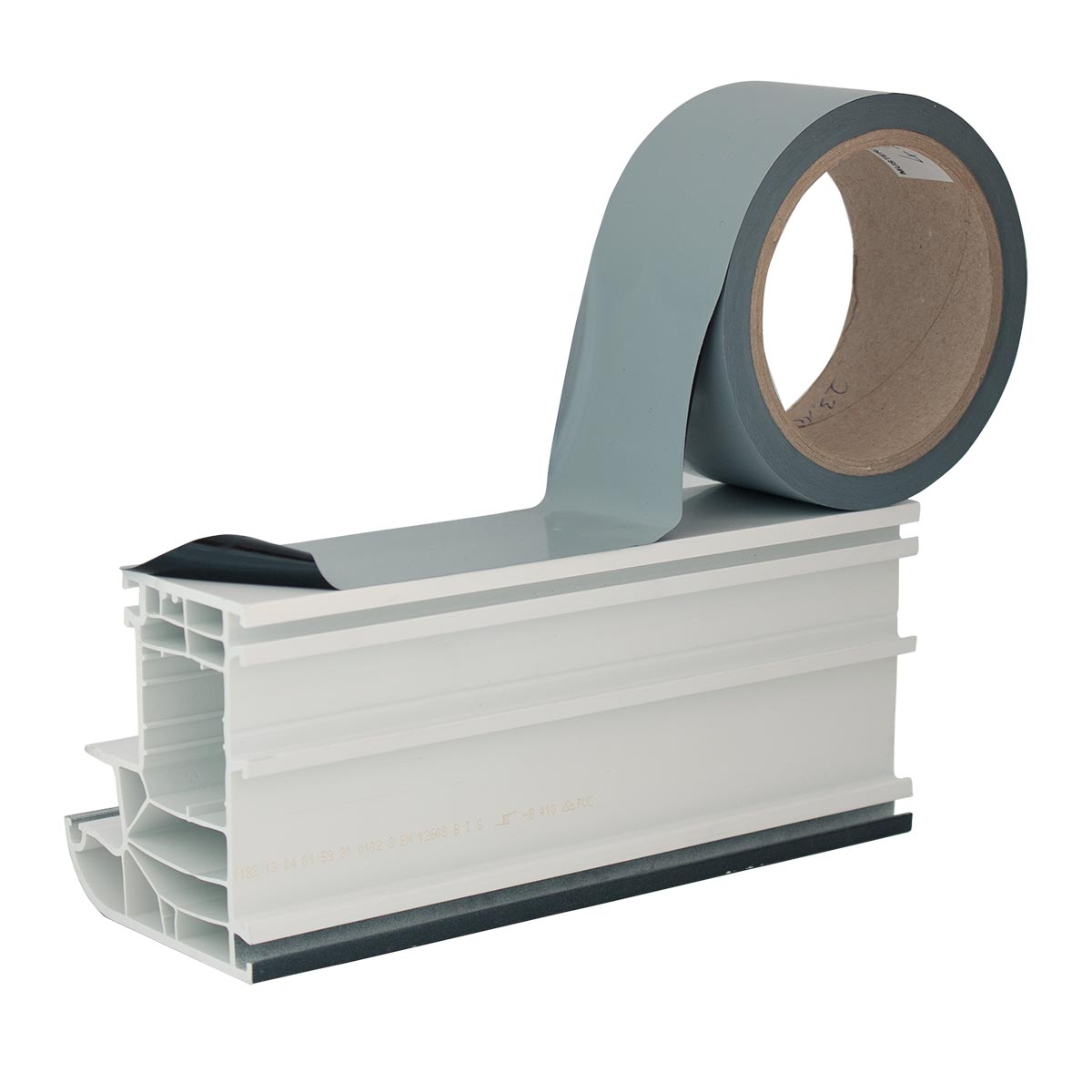

Protective films for glassware

Intended use

Protective films for temporary protection of glass surfaces.

During transportation and storage as well as during several construction phases, your glassware will be reliably protected from contamination.

Advantages

These films can be used for outdoor applications by UV-stable adhesives and provide easy removability.

Protective films for automotive industries

Intended use

Protective films for the temporary protection of all common surface qualities in the interior and exterior of automobiles.

Whether rough textured, grained or high gloss polished, aluminium, plastics or textiles – FFT will find a suitable solution with the right selection of adhesives, to protect your high-quality surfaces at any time.

Advantages

The easy removability, without leaving adhesive residues, is a prerequisite.

Protective films for textiles

Intended use

Carpet, artificial leather or fabric, FFT finds the best solution to optimally protect your surfaces by selecting the right carrier and adhesive.

Carpets can be reliably protected from dirt and light mechanical impact during the construction phase.

Qualities approved for maritime shipping are also available.

Advantages

Easy removability, without leaving adhesive residues, is a prerequisite. By selecting an “Easy-Peel” film, maximum productivity in further processing can be enabled.

Protective films for lacquered surfaces

Intended use

Protective films for temporary protection of painted surfaces with all common surface qualities.

Whether rough/textured, with different gloss levels or powder-coated, painted metals or woods, FFT will find the optimal solution to safely protect your high-quality surfaces by selecting the right carrier and adhesive.

Advantages

Highest adhesive strength on textured surfaces, it protects against mechanical damage, has excellent UV resistance and high visibility for the user. It can also be removed from appropriate surfaces without residue for up to 6 months.

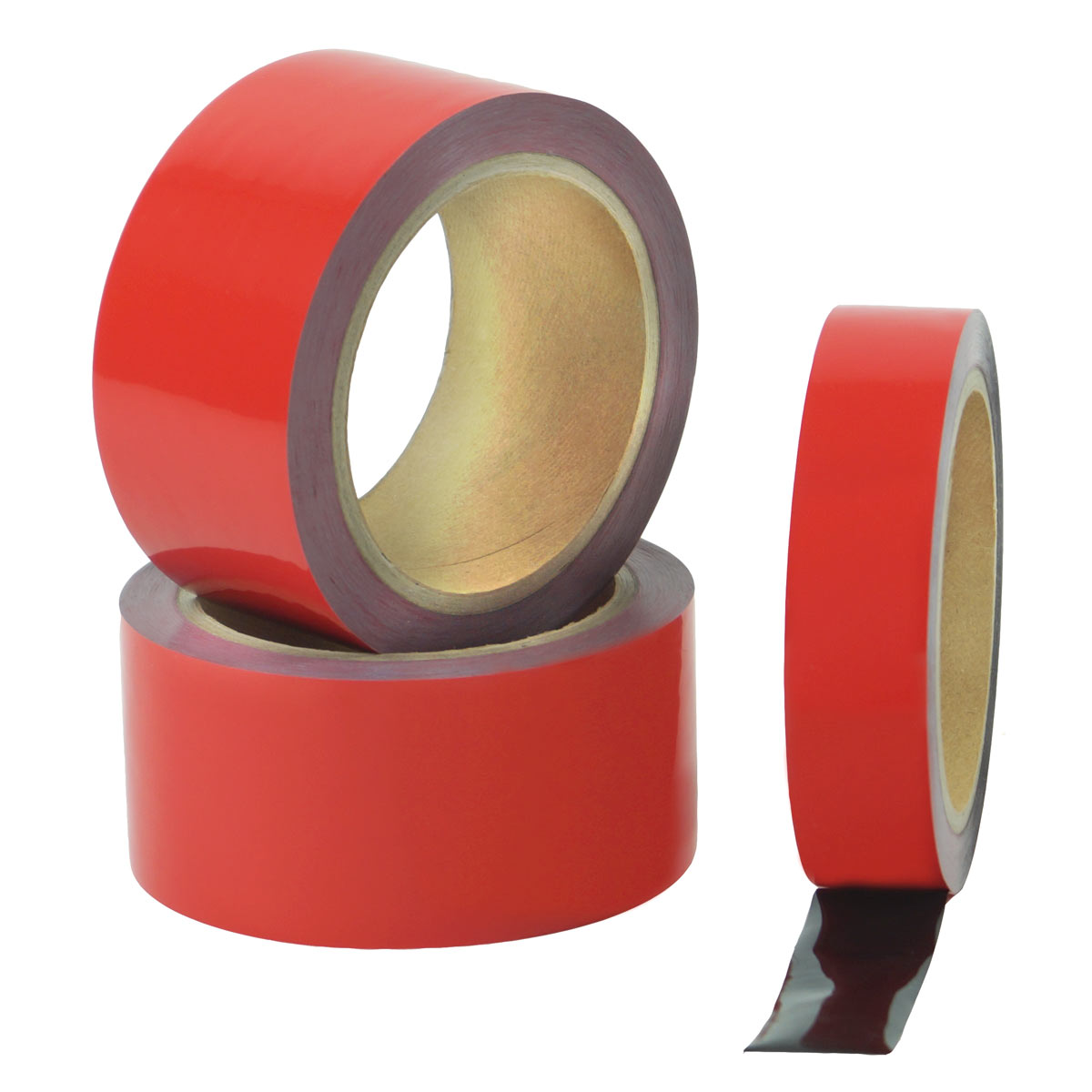

Protective film for textured surfaces

Intended use

Protective films for temporary protection of textured surfaces with all common surface qualities.

Rough-Guard Red is an in-house production of the FFT Group and the solution for the protection of rough and highly textured surfaces. It is available in individual widths.

Advantages

Highest adhesive strength on textured surfaces, it protects against mechanical damage, has excellent UV resistance and high visibility for the user. It can also be removed from proper surfaces without residue for up to 6 months.