Precision and flexibility

Further processing of our adhesive tapes and protective films on our state-of-the-art die cutting systems opens up impressive new possibilities for you! Excellent precision, flexibility in geometry and contour selection, as well as layouts adapted to the converting process, give us the chance to work with you to develop the optimum solution tailored to your application.

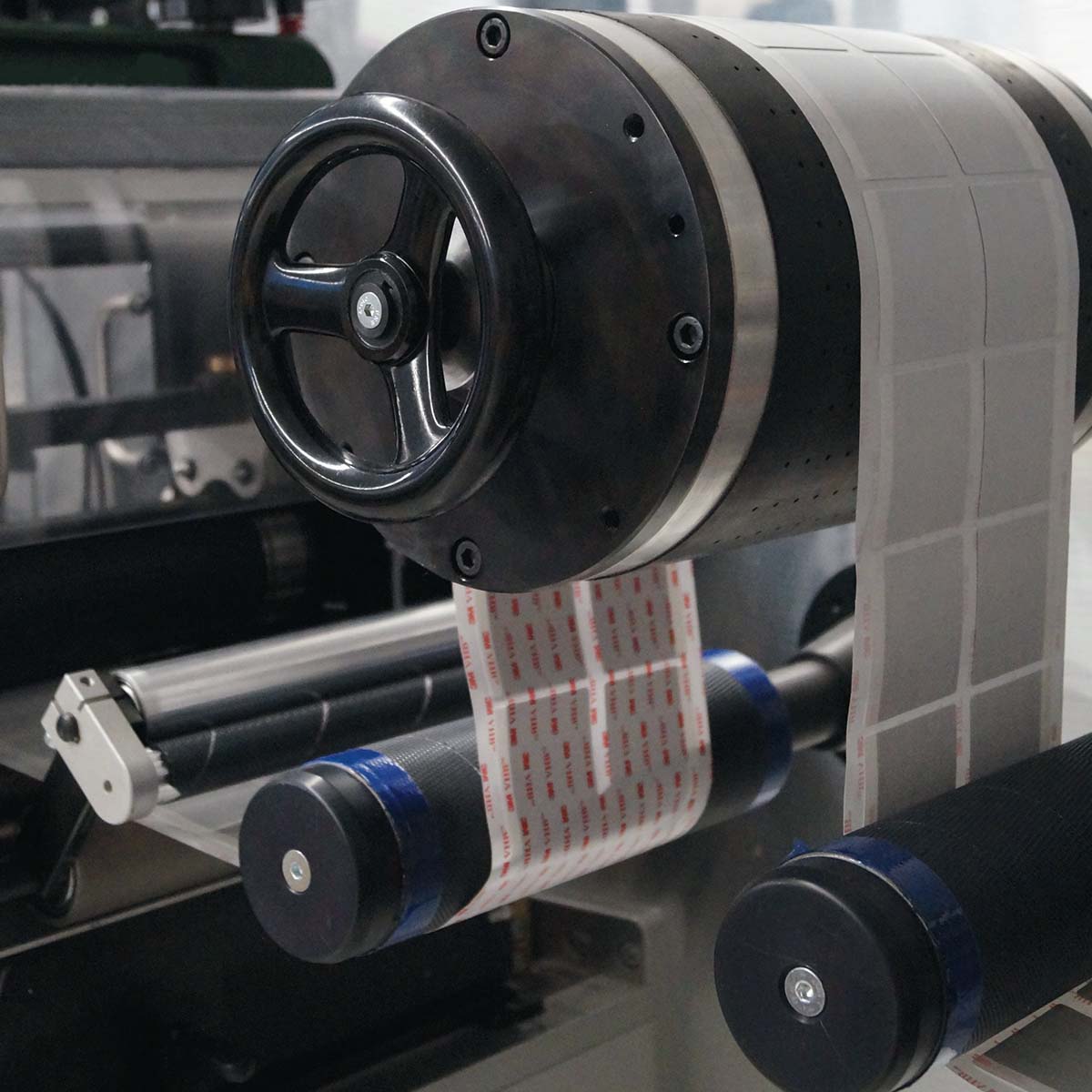

On roll

Die cut parts on the roll

The stamped parts lie on a carrier web of paper or foil and are wound lying inside or outside. Depending on the geometry and material, the parts may be “cut-to-cut” or spaced. The carrier web can be used at the same time as an aid for detaching the parts. We are happy to realize your individual or additionally desired grip.

We would also be happy to realize your individual or additionally desired touch tab.

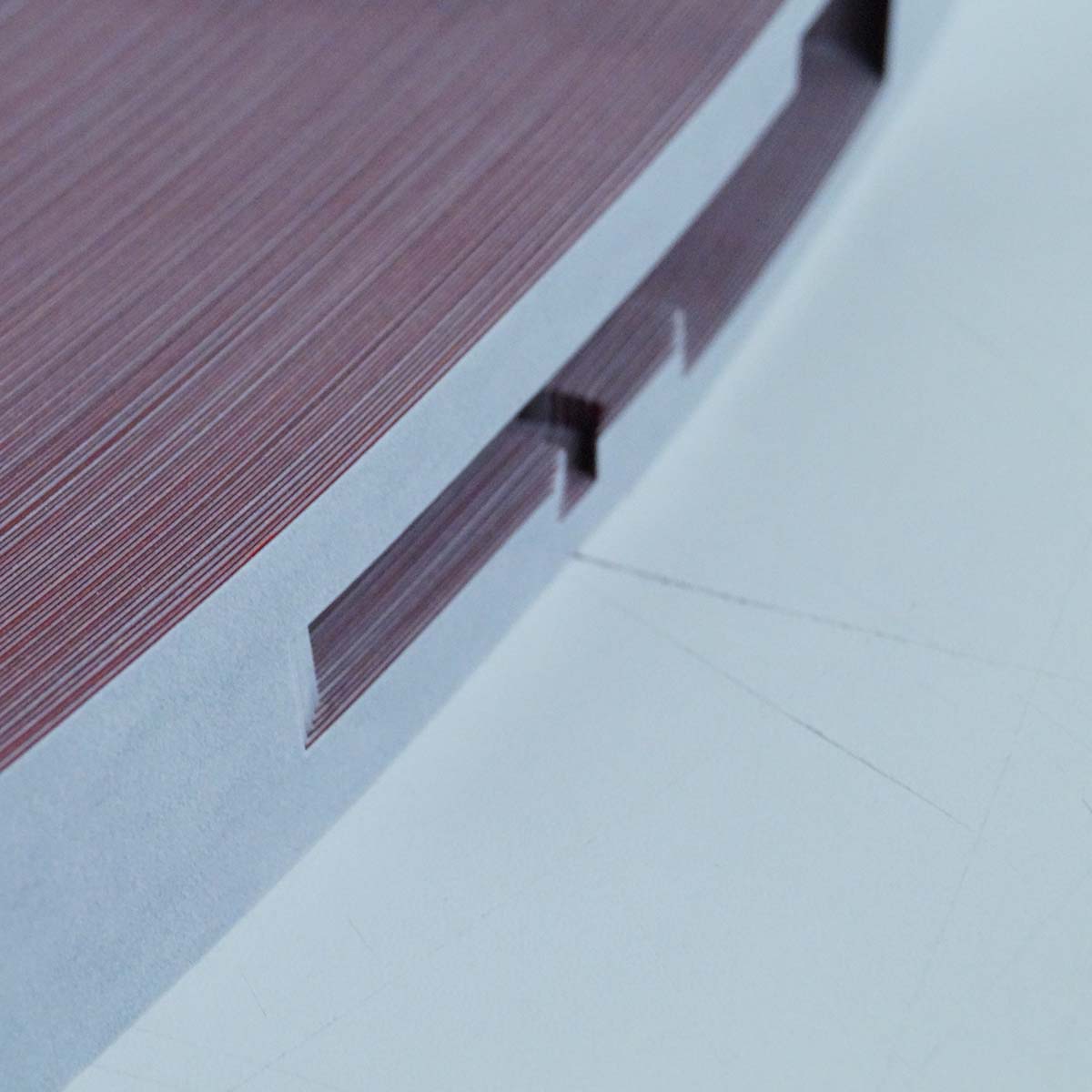

Sheet

Die cut parts on a sheet

A defined number of stamped parts lies on a carrier sheet of paper or foil. Depending on the geometry and material, the parts may be “cut-to-cut” or spaced. The carrier sheet can be used at the same time as an aid for detaching the parts.

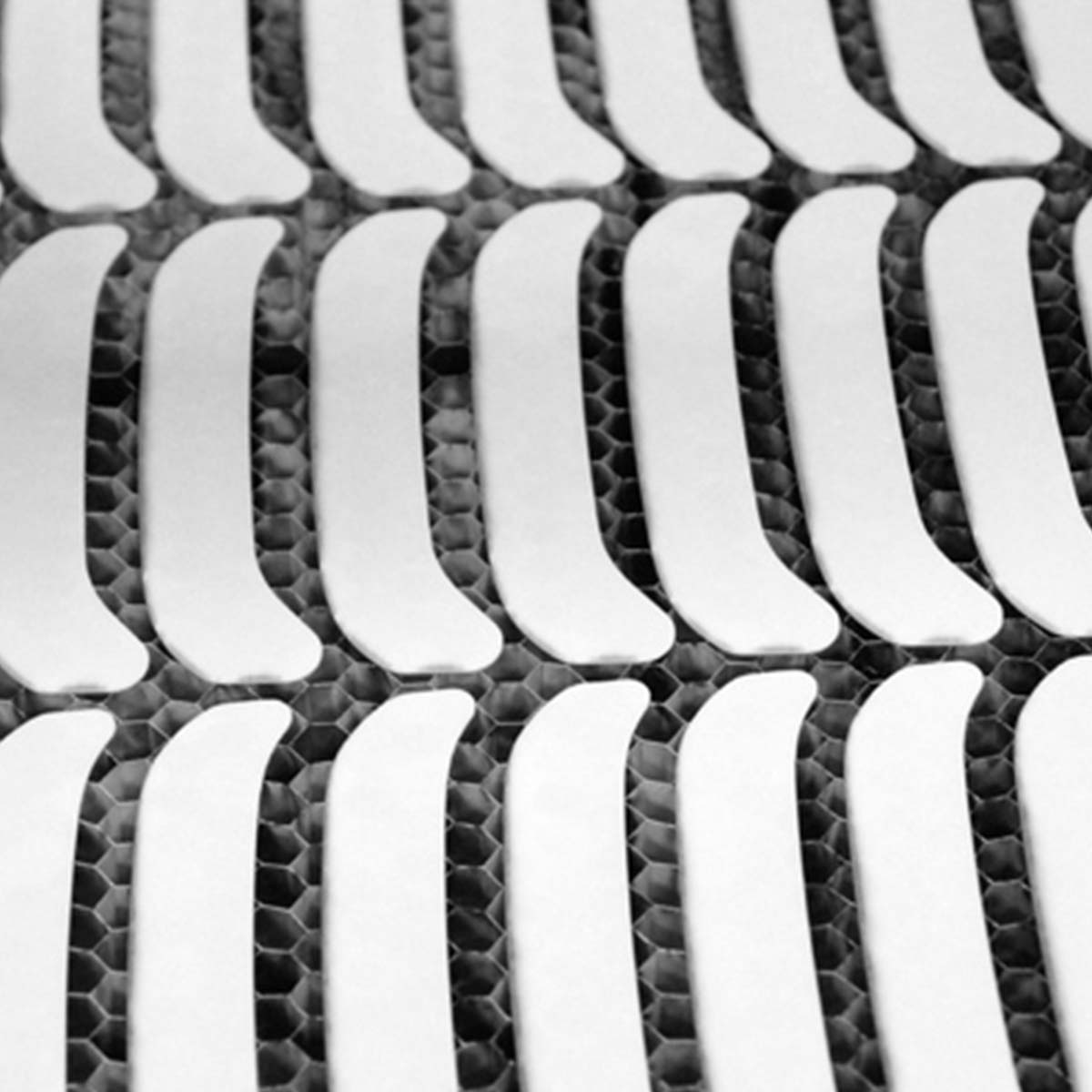

Separate parts

Separate parts

Each stamped part is cut in its contour and separated from other parts. A peel-off aid can additionally facilitate your process by peeling off the liner or by sticking on a handle.